Introduction The scientific name polyamide fiber is a g […]

Introduction

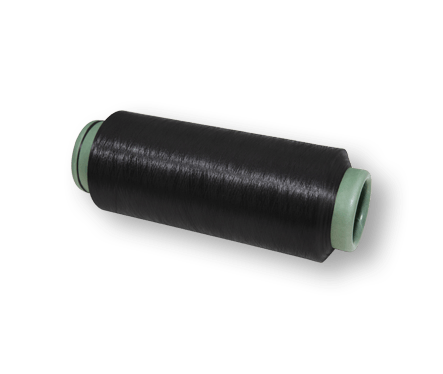

The scientific name polyamide fiber is a general term for polyamide fiber produced in China. Internationally known as nylon. High strength. Abrasion resistance and good resilience. Can be used for pure textiles and blended fabrics and knitted fabrics. The main varieties are nylon 6 and nylon 66, which have similar physical properties. Nylon is more hygroscopic and dyeable than polyester. It is resistant to alkalis but not to acids. Its fiber strength will decrease after long-term exposure to sunlight. Nylon has heat-setting characteristics, which can maintain the bending deformation formed when heated.

Nylon filaments can be made into stretch yarns, and staple yarns can be blended with cotton and acrylic to increase its strength and elasticity. In addition to applications in clothing and accessories, it is also widely used in industry such as cords, transmission belts, soft Tubes, ropes, fishing nets, tires, parachutes, etc.

Nylon definition

Nylon is the Chinese name for synthetic fiber nylon, which is also called "Nylon" and "Nylon". The scientific name is polyamide fibre, that is, polyamide fiber. Since Jinzhou Chemical Fiber Factory is the first factory in my country to synthesize polyamide fibre, it was named "Nylon". It is the earliest synthetic fiber variety in the world. Due to its excellent performance and abundant raw material resources, it has been widely used.

Nylon performance

Strong and wearable, ranking first among all fibers. Its wear resistance is 10 times that of cotton fiber, 10 times that of dry viscose fiber, and 140 times that of wet fiber. Therefore, its durability is excellent.

The elasticity and elastic recovery of the nylon fabric are excellent, but it is easily deformed under a small external force, so the fabric is easily wrinkled during wearing.

Poor ventilation and easy to generate static electricity.

The hygroscopicity of nylon fabric is a better variety among synthetic fiber fabrics, so clothing made of nylon is more comfortable to wear than polyester clothing.

Has good resistance to decay and corrosion.

The heat and light resistance are not good enough, the ironing temperature should be controlled below 140 ℃. Pay attention to the washing and maintenance conditions during wearing to avoid damage to the fabric.

Nylon fabrics are light fabrics, which are only listed after polypropylene and acrylic fabrics in synthetic fiber fabrics. Therefore, they are suitable for mountaineering suits and winter clothing.

Large varieties of nylon

There are many types of nylon, including nylon 6, nylon 66, nylon 11, and nylon 610. The most important ones are nylon 66 and nylon 6. The properties of various nylons are not exactly the same. The common feature is that there are amide chains on the main chain of the macromolecule, which can adsorb water molecules and can form a crystalline structure. It has excellent wear resistance and is an excellent clothing fiber.

Nylon fiber fabrics can be divided into three categories: pure spinning, blended and interwoven fabrics, and each category contains many varieties.

1. Nylon pure textile fabric Various fabrics woven with nylon yarn as raw materials, such as nylon taffeta e69da5e6ba903231313335323631343130323136353331333236376631 silk, nylon crepe, etc. Because it is woven with nylon filament, it has the characteristics of smooth feel, firm and durable, and moderate price. It also has the disadvantages that the fabric is easy to wrinkle and is not easy to recover. Nylon taffeta is mostly used for lightweight clothing, down jackets or raincoats, while nylon crepe is suitable for summer dresses, spring and autumn dual-use shirts, etc.

2. Nylon blended and interwoven fabrics Fabrics obtained by blending or interweaving nylon filaments or staple fibers with other fibers have the characteristics and advantages of each fiber. Such as sticky/jinhuada, it is made by blending 15% nylon and 85% viscose into yarn, which has double the warp density than the weft density, the texture of the body is thick, tough and durable, the disadvantage is poor elasticity, easy Wrinkles, wet strength drops, and it tends to sag when worn. In addition, there are sticky/jinfanliding, sticky/jin/wool tweed and other varieties, which are some commonly used fabrics.